Advantages for the Owner and the Skipper

- Most efficient electrically driven propulsion

- Increased cargo space

- Minimal training required for skippers

- Full power propeller shaft rotation in two directions

- Steering behavior similar to conventional propeller and rudder propulsion

- Lower installed power required

- Better maneuverability

- Improved course stability

- Low noise and vibration levels

- Low maintenance costs

- Complete spare parts stock available

- Shorter repair and maintenance turnaround times

- Extensive remote status and performance monitoring

Advantages for Shipyards and Designers

- More design freedom, enabling larger cargo space

- Modular design

- Simplified engine room layout, e.g., no need for hull work or alignment of the propeller shaft

- No coolers required for the PM electric propulsion motor

- Simple hull shape and construction

- Fewer provisions needed for vibration and noise reduction

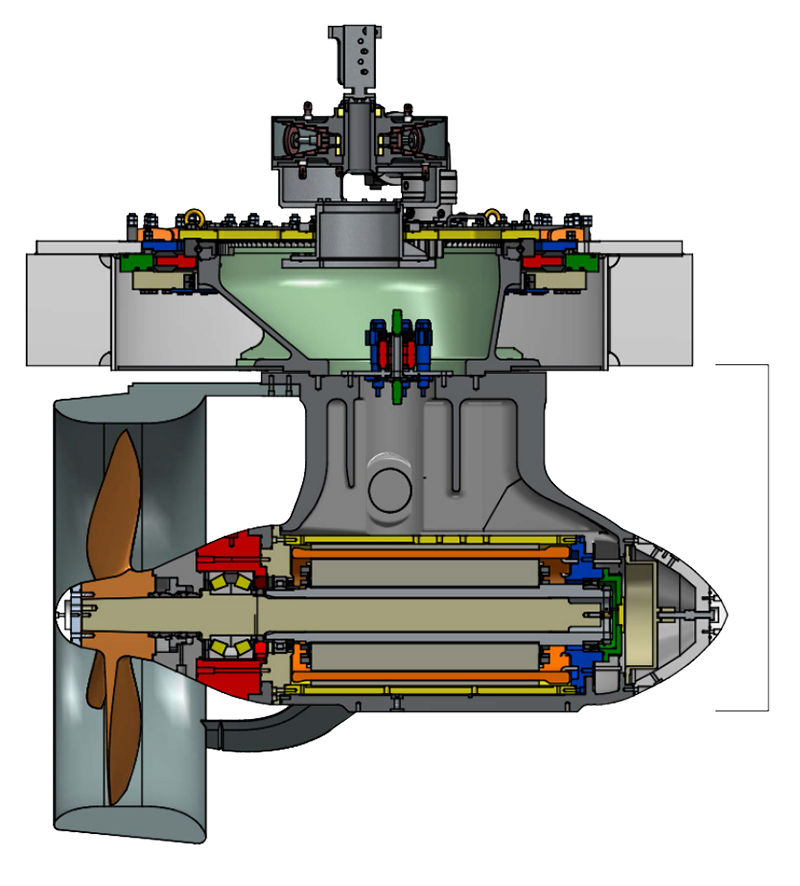

Design

Verhaar Omega’s EQUADRIVE® systems are designed using the latest maritime propulsion insights and CFD analyses.

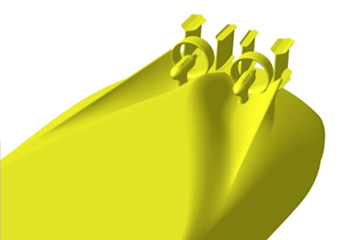

The pull propeller setup benefits from asymmetrical supports, which further reduce the fuel consumption of the EQUADRIVE® (see the image below).

For achieving minimal fuel consumption and maximum added value, Verhaar Omega recommends integrating the hull design and the EQUADRIVE® for the intended operational profile.

The length and shape of the support add a rudder effect to the steering EQUADRIVE®. This improves the course stability of the EQUADRIVE® propulsion. The optional "Course Stability Fin" can be mounted beneath the EQUADRIVE®.

of the EQUADRIVE®

Technology

The EQUADRIVE® has an extremely robust and simple design. The best available components and control systems are used for maximum reliability, longevity, and ease of maintenance.

The main technical features of the EQUADRIVE® are:

- Full power propeller shaft rotation in two directions

- Steering motion is electrically driven

- Direct drive of the propeller shaft without gears

- Minimum number of components

- Double sealing with indicator fluid

- Oil-filled EQUADRIVE® housing with onboard stand tank

- No coolers needed for the PM motor

- The design lifetime of the bearings is unlimited

- Easy exchangeable PM-motor (Cartridge)

Fully Oil-Filled

- In-house developed remote control systems for:

- Power

- RPM

- Steering angle

- Bearings

- Temperatures

- Pressures

- Indicator fluid

- Oil (Water, ∆P filters)

Key Benefits of the Robust Design and Technological Features:

- No coolers needed for sealing coolant and lubrication oil of the PM motor

- Extremely long service life

- Low repair and maintenance costs

- Fast exchange of damaged parts (within one workday)

- Very quiet and vibration-free operation

- Flexible mounting supports are often unnecessary

- Improved course stability

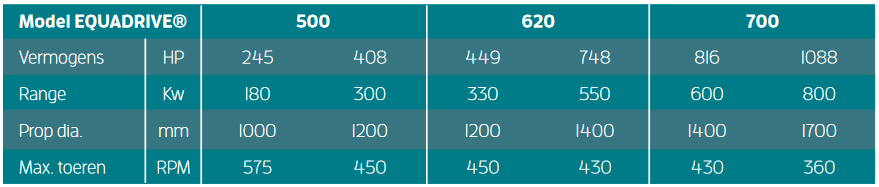

Specifications

Features

Standard

- One-directional nozzle for maximum fuel efficiency

- Push propeller setup

- Symmetrical rudder shape for the support

- Steering angle 2 x 210 degrees, without slip rings

- Full power propeller shaft rotation in two directions

- Includes mounting flange for EQUADRIVE® installation

- 5 propeller blades, Cunial

- Verhaar Omega control system

Standard

- Unlimited steering angle with slip rings

- Alternative configurations:

- Fixed installation

- Pull propeller

- Asymmetrical wing shape of the supports

- Detachable course stability fin

- Flexible mounting in the ship

- 3 or 4 propeller blades

- Open propeller

- Classification (Lloyds, other classification societies on request)

Research and Development

The application of the EQUADRIVE® shows significant reductions in fuel consumption compared to the current state of the art. This conclusion has been drawn based on, among other things:

- CFD analyses of currently widely used propulsion systems, compared to the EQUADRIVE® in different types of ships and usage profiles.

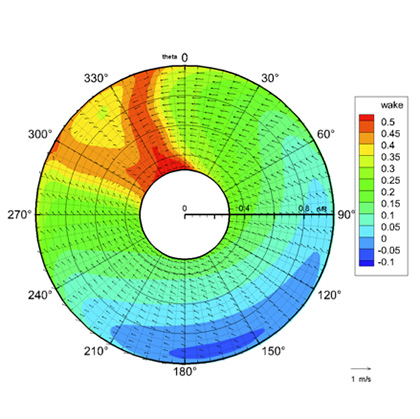

Double Screw Design

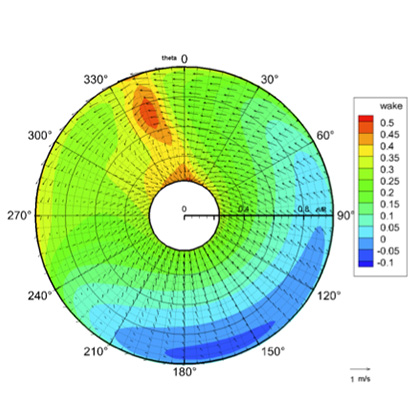

Equadrive Design

Nominal wakefield at propulsion plane (PP), Double screw concept (left);

Equadrive propulsion concept (Right) for Case 1. CFD output Inland transport vessel

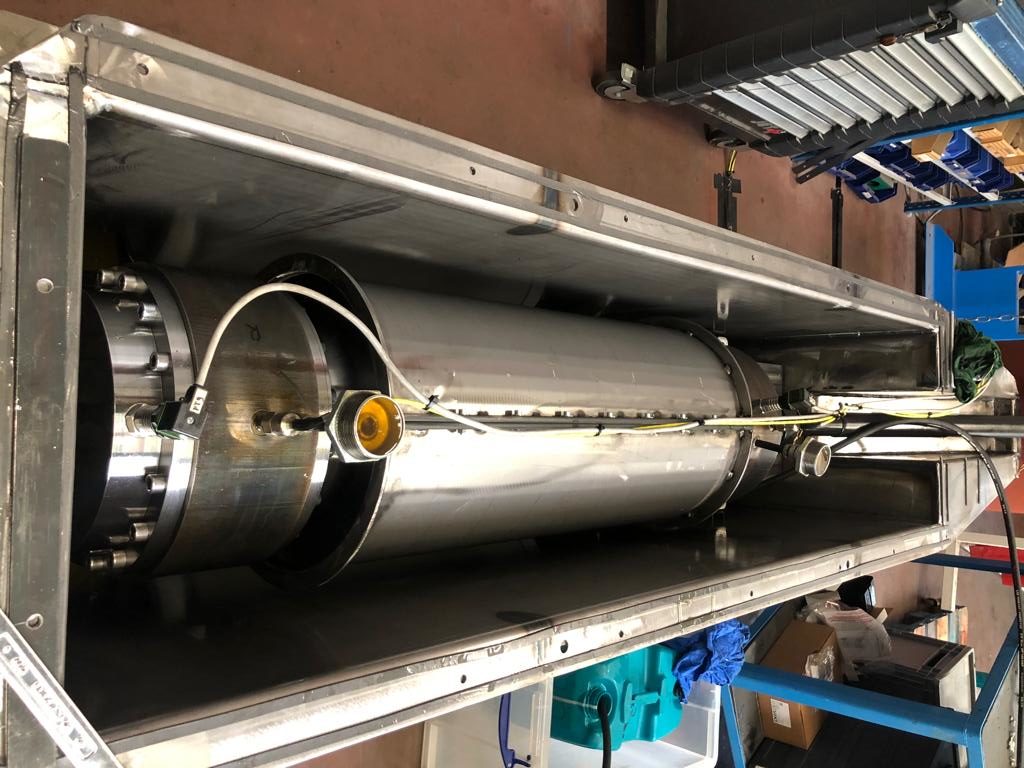

Performance test of the oil-filled PM motor

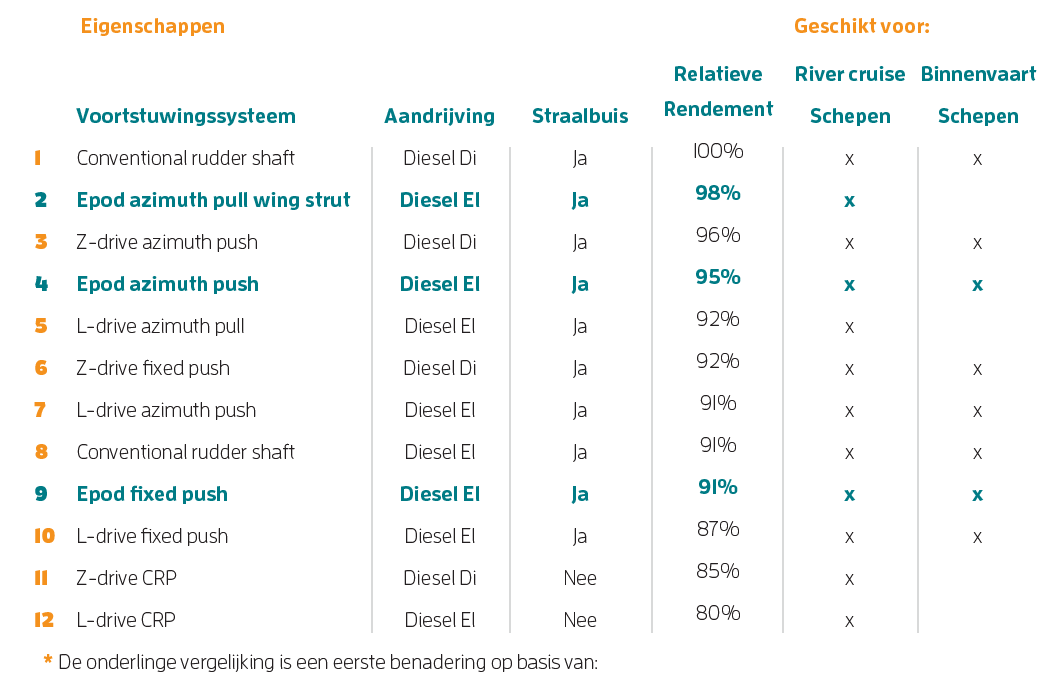

Research into various propulsion systems, ship types, and sailing profiles resulted in an indicative hierarchy of total fuel consumption for propulsion, as shown in the table below.

Comparison of total fuel consumption for various propulsion systems.

* The most efficient system is at the top

- CFD calculations for different types of ships, propulsion systems, sailing profiles, expert consultations, and optimal integration of the propulsion system into the ship's hull lines.

- The table above is the result of careful research. However, results may vary for specific design combinations and sailing profiles.

Want to know more?

Make an appointment

T: +31 (0)252 745 300

E: info@verhaar.com

Visiting address

Taanderstraat 20

2222 BE Katwijk

On appointment

Augustapolder 32

2992 SR Barendrecht

© 2022 Verhaar Omega | Privacy Statement